Equipment Sale

Starting from consulting, the optimal plant design

Casting plant and equipment needed for manufacturing, it will vary depending on the conditions for the user. We collect information based on a variety of production space and budget Foundry work environment; we make suggestions for the best starting point for consulting mechanical alterations.

Casting technology in history has been cultivated since ancient times. Meanwhile, each time repeating the technical innovations, we developed the art in modern life and industry to support.

We provide the best information on the latest casting machine to produce significant innovations of industrial products.

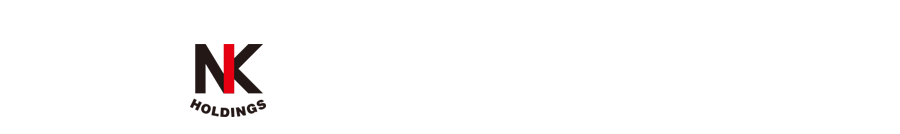

Molding machine

|

AMFV-Ⅱ Space-saving single stations |

|

AMFV-ⅡS Easy slide into the lower core frame Single Station |

|

AMFV-Ⅲ 2 Station into the lower mold core, easy |

|

AMFV-Ⅳ 18 second cycle, two station |

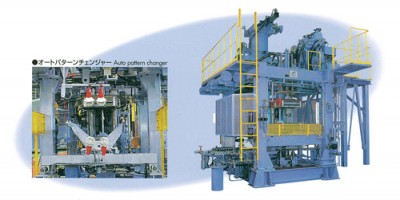

Automatic pouring machine

|

PCF Features ■ High-speed pouring system The adoption of vertical pouring nozzle, pouring improves the accuracy of control, keepstability achieved. can only tune in to the line with the installation Encoder in the pussha and line production. Can be installed directly in line with existing Pittoresu。 |

Sand cooling system

|

H Drum Sand collected in the tank. Rotates continuously to the consistency of damp sand with the recovery of degradation. |

SAND MIXER

|

DEV-22 Japan-made high-speed mixer EIRICH

|